HyWaves has completed the first phase of comparison testing for its H2Top Power Management and Control Architecture, as part of a comparative test programme showing the HyWaves System to outperform the best conventional solar-to-hydrogen architectures while offering a vastly reduced cost:

- Economics: For an example 100 MW hydrogen plant, including a healthy profit margin, the HyWaves system will lead to an 80% reduction of the typical cost of conventional DC-DC power electronics, delivering a typical CAPEX saving of around $15+ million (current conventional) or $6+ million (Nearest Future Competitor – DC/DC ) over the facility’s lifetime.

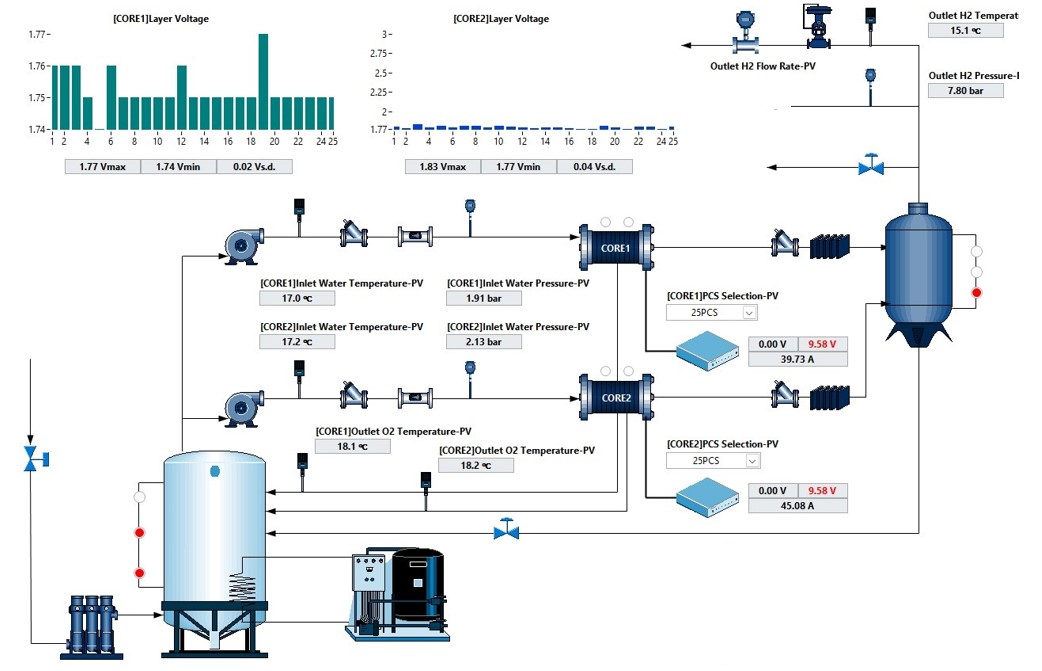

This stage benchmarked the system against a DC/DC converter-based architecture using physical testing alongside projected results from a conventional AC-linked approach. This latest testing follows the recent announcement of successful TRL 6+/7 validation and continues HyWaves’ structured development path toward commercial readiness.

While typical solar-to-hydrogen sites use a conventional architecture based on solar inverters exporting power to either a local or national AC electrical grid, some companies now offer DC/DC converters suitable for facilities with solar-to-hydrogen production. This approach represents the best-case scenario for conventional power electronics in terms of power transfer efficiency, but it still requires more complex integration and significantly higher investment costs compared to the HyWaves system.

Our comparative benchmark testing aimed to establish whether the HyWaves system could offer equivalent performance to the much more costly DC/DC converter approach. Additionally, the HyWaves system was benchmarked against a simulated AC-coupled system using a local grid, which is the approach used by the majority of current operational solar-to-hydrogen plants.

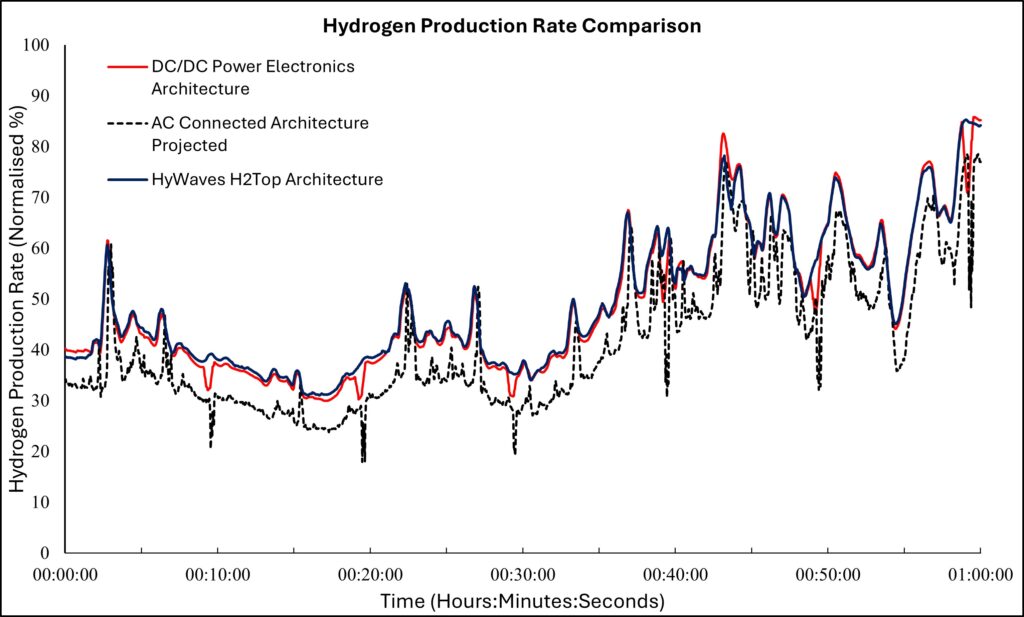

The results confirm equivalent performance across multiple hours of testing while demonstrating 3–4% higher electrical power efficiency under real-world solar conditions compared to the highest performing DC/DC-based systems.

- The hydrogen yield was in the range of 99–103% of the compared DC/DC architecture across 15 hours of testing, split into four separate tests to ensure a range of solar irradiances was captured under varying weather conditions.

- The HyWaves Generation-2 System was used for this testing, which does not include the solar pyranometer-enabled rapid tracking response of the upcoming Generation 3. The company’s simulation tool estimates this will increase average hydrogen production by up to 2–3% under variable weather conditions.

The full results will be published in the HyWaves Field Testing Report, which will detail the test facility and protocol used. This report will be available on request to industry stakeholders and eligible investors. A one-hour sample of the hydrogen production rate comparison is shown below:

During this test, the HyWaves system consistently offered superior performance over both the benchmark DC/DC converter approach and the solar-connected AC grid (projected). The sample was taken during variable weather conditions to showcase the HyWaves controller’s ability to manage power flow under changing solar irradiance.

At HyWaves, we continue to advance the HyWaves System platform toward commercial deployment as an efficient and scalable power-management architecture for renewable hydrogen production. The system offers significant reductions in both capital cost and operational expenses compared to other architectures in the market.

Next Steps:

- HyWaves Field Testing Report to be available to industry stakeholders and eligible investors: November 2025

- HyWaves System Generation-3 launched: November 2025

- HyWaves System integration and initial field testing with the ZTT Alkaline-based electrolyser: December 2025